Introduction:

Diesel driven pumps are versatile machines that play a crucial role in various industries for fluid management applications. In this article, we will explore the functionality, advantages, and applications of these powerful pumps, highlighting their significance in efficiently handling fluids.

Understanding Diesel Driven Pumps:

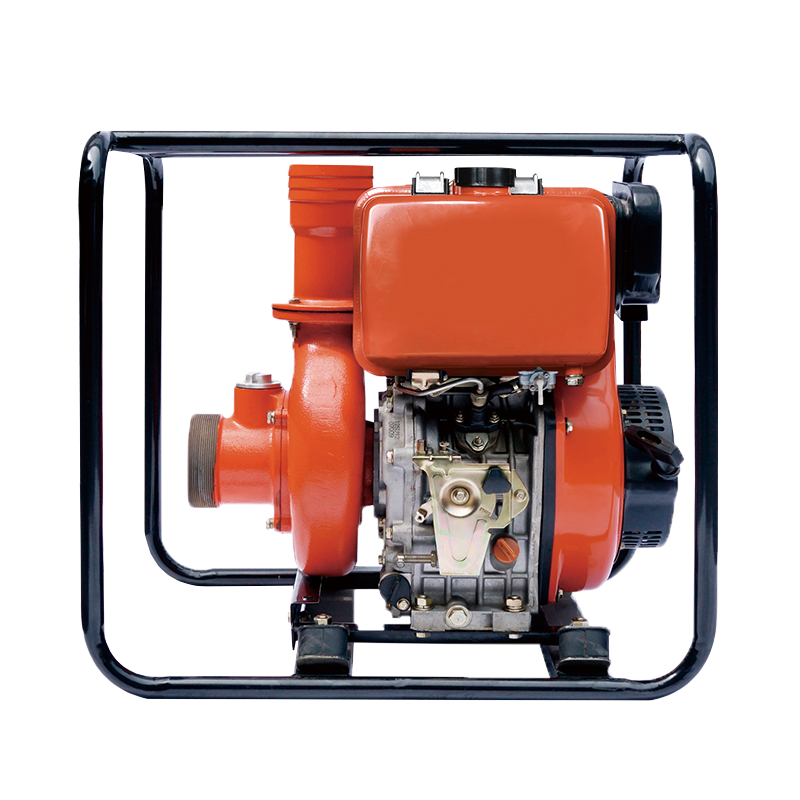

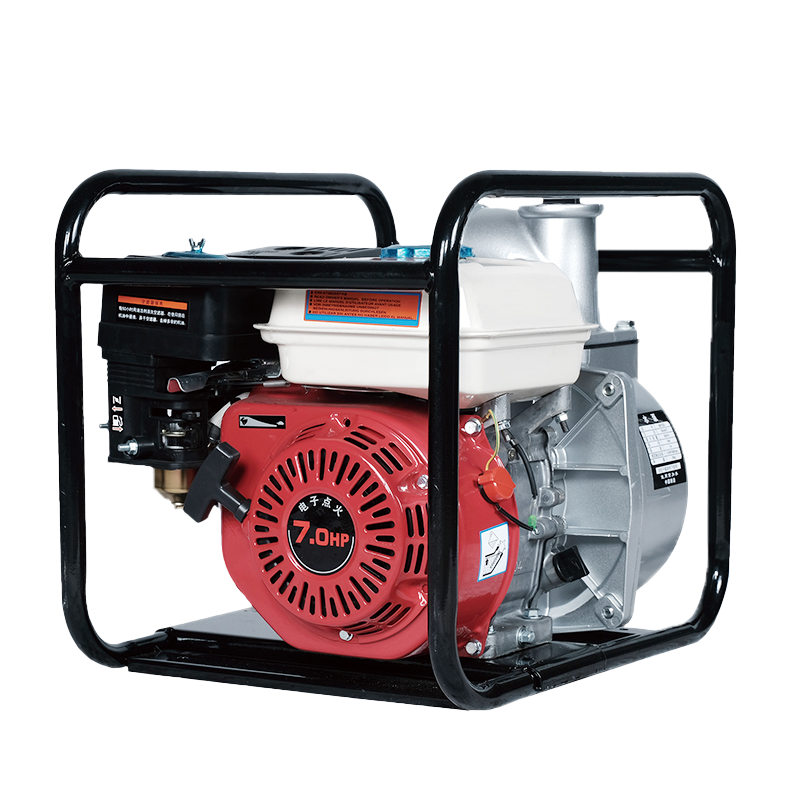

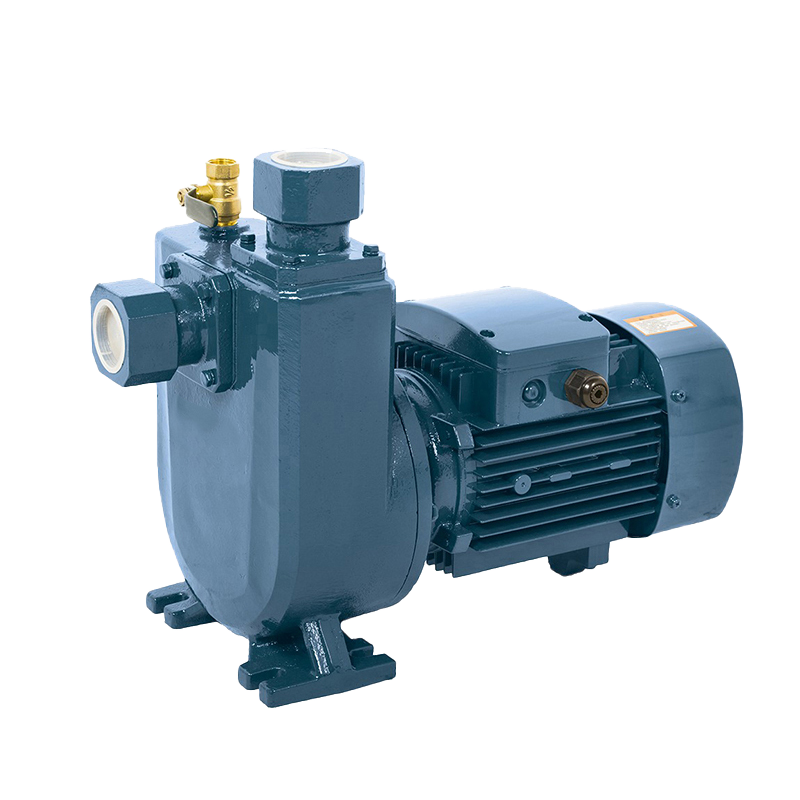

Diesel driven pumps are robust devices that utilize diesel engines to generate power for fluid pumping. They are commonly used in situations where electricity supply is limited or unavailable, offering a reliable and independent solution for fluid management.

Working Principles:

a. Diesel Engine: The pump is powered by a diesel engine, which drives the pump mechanism and provides the necessary energy for fluid transfer.

b. Impeller Action: The pump's impeller creates centrifugal force, drawing in the fluid and propelling it outward, generating the required pressure for efficient fluid movement.

c. Self-Priming Capability: Many diesel driven pumps feature self-priming functionality, allowing them to automatically remove air from the system and maintain optimal performance.

Key Advantages and Features:

a. Portability and Mobility: Diesel driven pumps are often designed with a compact and portable structure, allowing for easy transportation and deployment in various locations.

b. Independent Power Source: Their reliance on diesel engines grants them the ability to operate independently, making them suitable for remote areas or emergency situations.

c. High Flow Rates and Pressure: These pumps are known for their ability to handle large volumes of fluids and deliver high-pressure output, ensuring efficient fluid transfer and distribution.

d. Versatility: Diesel driven pumps can handle different types of fluids, including water, fuels, chemicals, and even solids-laden liquids, making them versatile for a wide range of applications.

e. Durability and Reliability: Built with rugged materials and components, these pumps are designed to withstand demanding environments and provide long-lasting performance.

Applications of Diesel Driven Pumps:

a. Agriculture and Irrigation: These pumps are widely used for agricultural irrigation, water transfer, and drainage in farming applications.

b. Construction Sites: Diesel driven pumps efficiently handle dewatering tasks, ensuring proper water management and site safety during construction projects.

c. Emergency Response: In emergency situations such as flood control or firefighting, diesel driven pumps serve as reliable tools for rapid water removal or fire suppression.

d. Mining and Industrial Operations: These pumps are essential for managing water levels, wastewater, and slurry in mining and industrial processes.

Maintenance and Safety Considerations:

Regular maintenance, including fuel and oil checks, filter replacements, and inspections, is crucial to ensure optimal performance and prevent breakdowns. Adherence to safety protocols and proper handling of flammable materials are essential for safe operation.

Conclusion:

Diesel driven pumps provide a powerful and versatile solution for fluid management across various industries. With their independent power source, high flow rates, and durability, these pumps play a vital role in ensuring efficient fluid transfer and distribution in diverse applications.

English

English عربى

عربى

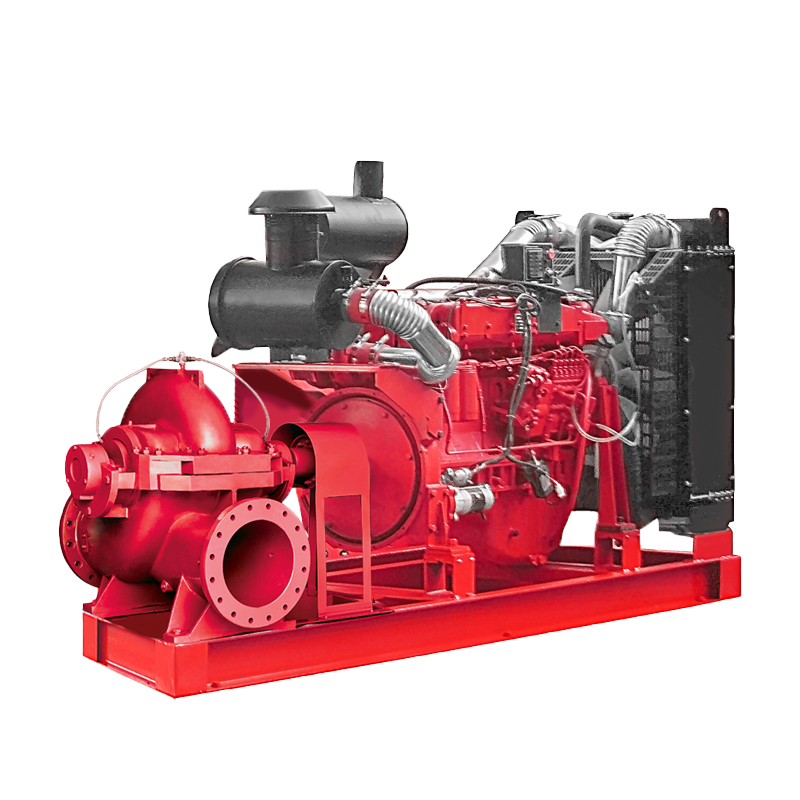

Fire Pump and System

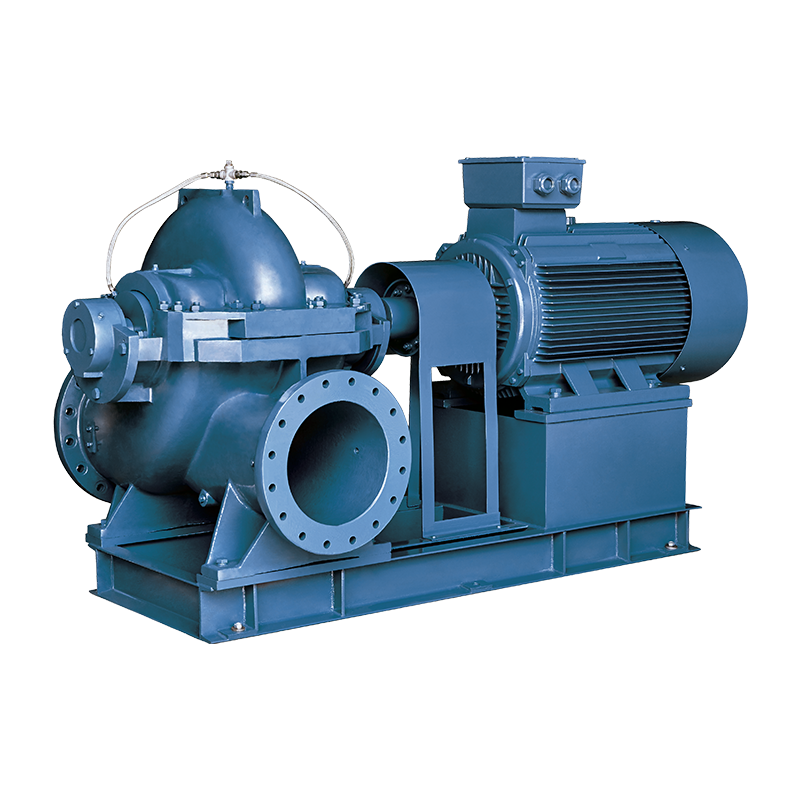

Fire Pump and System Split Case Pump

Split Case Pump Engine and Pump

Engine and Pump Long Shaft Pump

Long Shaft Pump Multistage pump

Multistage pump Water Supplier System

Water Supplier System Sewage Pump

Sewage Pump Industrial Pump

Industrial Pump Self-Priming Pump

Self-Priming Pump Inline Pump

Inline Pump Domestic Pump

Domestic Pump Electric Motor

Electric Motor Borehole Pump

Borehole Pump